Electric vehicle lithium battery liquid cooling method recommended

From my personal point of view, the most reliable way to manage the thermal management of a battery pack is similar to the following.

From a reliability point of view, I will evaluate the manufacturing reliability of tesla's 18650 cylindrical battery and the reliability of its internally connected fuses. Tesla's battery pack is inherently low-cost. This is because the cost of the 18650 battery itself is low, but in order to ensure the serialization and cascading between small batteries, it takes a lot of safety considerations. So many fuse connections can be very difficult for large-scale production. Toyota has a strong presence on new energy vehicles, but after its electric car plan suffered severe setbacks, there were few attempts at large-capacity batteries. In essence, its plug-in prius is more biased towards hybrid cars.

Summarize some of the features of doing this:

1. The battery pack can be made very compact with almost no gaps in between.

2. Shock and impact resistance is better, and a shock absorbing cushioning material can be added between the batteries CELL.

3. The process of heat dissipation is converted into a heating process, so that the operation of the lithium battery at low temperatures is guaranteed.

4. Guarantee the uniformity of heat dissipation of the battery CELL.

5. The cost is relatively high, mainly in the price of high-pressure pumps and polymer batteries, both of which have great room for price reduction.

6. Safety, the safety of the polymer battery itself is easy to manage.

In this paper by SAE, the authors mentioned the simulation method for module cooling. Integrated Simulation Process for the Thermal Management of LiIon Batteries in Automotive Applications

Overall, this article is somewhat theoretical, and there are some problems with the entire design.

In this paper by SAE, the Thermal Characterization & Management of PHEV Battery Packs (Compact Power, Inc) for polymer batteries is described in more detail.

The structural design of the internal flow path of the heat sink also has a certain influence on the distribution of water flow and the efficiency of heat dissipation (heating), which directly affects various parts of CELL (this CELL is generally a large cell in which several batteries are connected in parallel). The temperature is not uniform.

Delphi's proposal for the first half (recommended for electric vehicle lithium battery liquid cooling method (top)) is patented. I don't know if it means that such a structure cannot be used (as shown in Figure 1):

Since liquid cooling only removes heat from the inside of the battery pack, more problems need to be solved. GM is currently the most complete and interested, please refer to some of the heat dissipation diagrams of VOLT.

The point to mention here is that the thermal design of the entire electronic product (including motor, motor controller, DC/DC high-voltage conversion and charger, the most special is the battery in the process of transplanting the industrial system into the car). Group) The heat dissipation requirements of these components need to be strictly considered. As previously summed up, in the case of a hot day, the car not only has to withstand the ambient temperature of the ground above 40 degrees, but also dissipates the heat from the passenger compartment. These devices on the chassis face systematic The risk of thermal management.

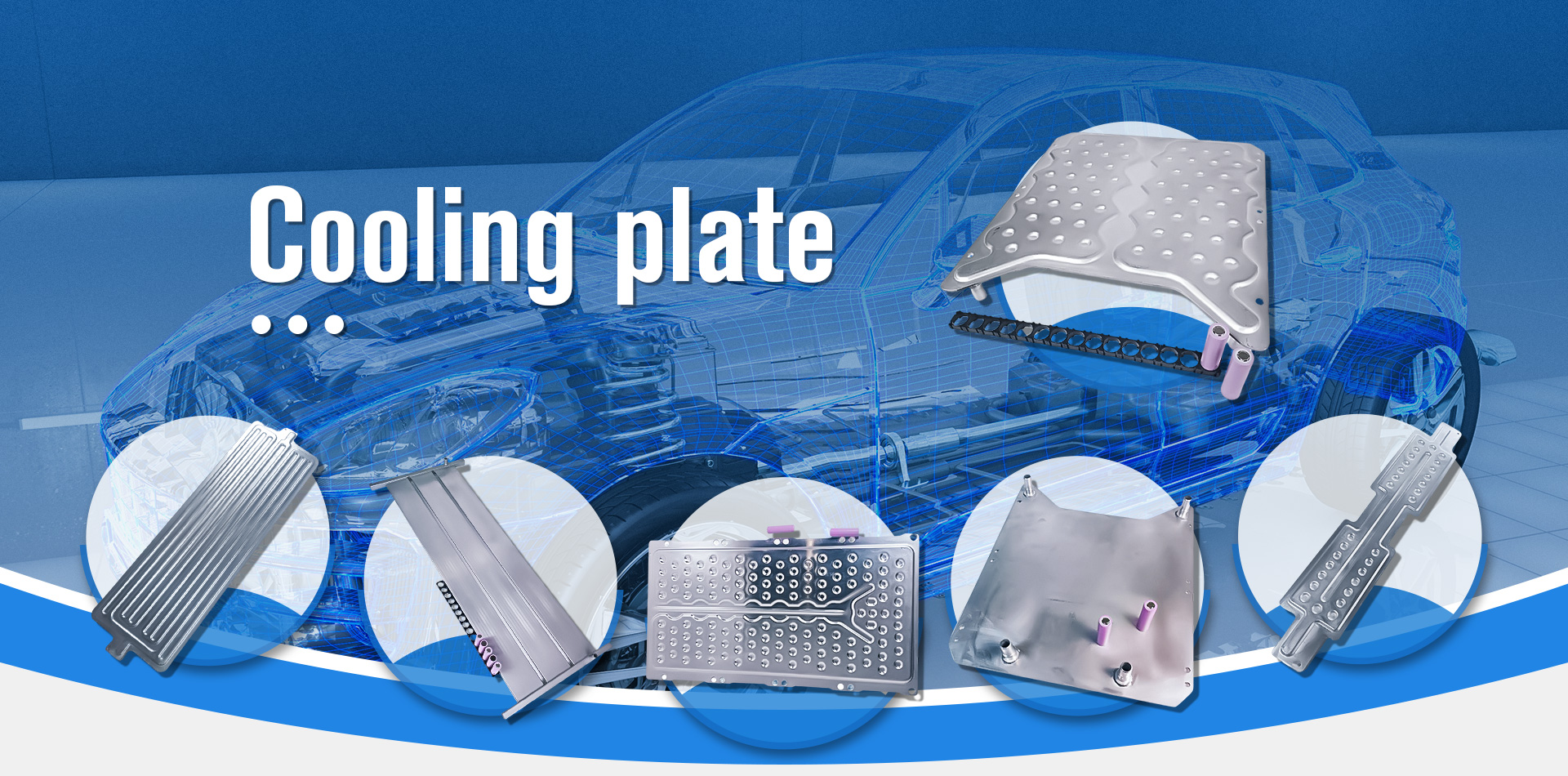

figure 1

I can't always understand that the current Chinese DC charging standard will bring much damage to the electric bus battery pack. Secondly, I can't understand the 32A special car charger. According to the Chinese voltage, it should be 6.6KW. Manufacturers have come with chargers that are not liquid-cooled; the cruel fact is that in order to meet most of the region and more demanding requirements, suppliers in Korea, Japan and the United States use liquids at charger levels above 2.2 kW. cool down. This is of course related to the car's system, and the domestic technology is too advanced.

The whole cooling system has relatively systematic control requirements, especially for the battery, it needs to have different heat dissipation control algorithms like the thermal insulation equipment to ensure the battery pack is in the proper temperature range and ensure the monomer in the battery pack. Temperature uniformity. In the process of analysis, I think it may take a few steps to get a set of design results:

1. Estimate the working conditions of the battery pack to be discharged and charged by the working condition of the whole vehicle;

2. Use simulation to verify the above conditions;

3. Estimate the heat generation of the battery pack under discharge and charging conditions by estimation;

4. Consider the choice of the system (liquid and air cooling); Note: In fact, further subdivision is required, see "HEV Battery Heat and Heat Considerations".

5. Consider the heat dissipation conditions required for the single cell with normal values;

6. Under the given heat dissipation conditions (liquid cooling is the inlet water pressure and temperature, air cooling is the power of the fan and the air temperature control of the air inlet) to design the corresponding heat sink or heat dissipation gap;

7. Simulate the results with fluid design software.

This kind of step may be a bit too simple. I am in the category of the contact with the system. I hope to communicate with you and improve the design level.

Author:

Ms. Tracy

Phone/WhatsApp:

+86 13584862808

E-mail naar dit bedrijf

Author:

Ms. Tracy

Phone/WhatsApp:

+86 13584862808